Bullet Resistant Glass Standards

When considering force protection for a building or safe room four areas must be considered: Blast, Ballistics, Forced Entry and Storm Impact. United States Bullet Proofing has expertise in all of these areas resulting in a more robust product even when protecting against a single threat.

Ballistics

The ratings for levels of bullet resistant glass are calculated by the protection the glass offers, based on the number of rounds fired before it breaks as well as the size of the weapon used. The projectiles fired by high-caliber, high-velocity weapons deliver the greatest amount of force to the target. This requires higher bullet resistant glass levels, which indicate a higher capacity for absorbing energy from the projectile. To be at the highest bullet proof glass levels, the entirety of the system — including the glazing material, frame and anchors — must be capable of absorbing the force from the projectiles. Simply having bullet proof glass installed in the framing system is not enough. The entire system must be rated highly enough to ensure the maximum level of protection. Our engineers design blast protection doors and windows that achieve the level of security your facility needs.

Ballistic Standards

The most common ballistic standards are UL 752 and the National Institute of Justice (NIJ). Both are summarized below. When ordering products, please specify the required level of ballistic protection.

UL 752 Ratings of Bullet Resistant Materials

| Protection Level | Ammunition | No. of Shots |

|---|---|---|

| Level 1 | 9mm Full Metal Copper Jacket with 3. Lead Core | 3 |

| Level 2 | 357 Magnum Jacketed LeadSoft Point 3. | 3 |

| Level 3 | 44 Magnum Lead Semi-Wadcutter 3. Gas Checked | 3 |

| Level 4 | 30 Caliber Rifle Lead Core Soft Point(.30-06 caliber) | 1 |

| Level 5 | 7.62mm Rifle Lead Core Full Metal Copper 1 Jacket, Military Ball (.308 caliber) | 1 |

| Level 6 | 9mm Full Metal Copper Jacket with 5 Lead Core | 5 |

| Level 7 | 5.56mm Rifle Full Metal Copper Jacket with 5 Lead Core (223 caliber) | 5 |

| Level 8 | 7.62mm Rifle Lead Core Full Metal Copper | 5 |

NIJ Standard 0801.01 Ballistic Resistant Protective Materials

| Armor Type | Test Ammunition | Rqd. Hits per Specimen |

|---|---|---|

| I | LRHW Lead 38 Special RN Lead | 5 5 |

| II-A | 357 Magnum JSP 9mm FMJ | 5 5 |

| II | 357 Magnum JSP (higher velocity round) 9mm FMJ (higher velocity round) | 5 5 |

| III-A | 44 Magnum, LeadSWC Gas Checked 9mm FMJ | 5 5 |

| III | 7.62mm, 308Winchester FMJ | 5 |

| IV | 30-06 AP | 1 |

AP – Armor Piercing

LRHV – Long Rifle High Velocity

FMJ – Fu MetalJacket

RN – Round Nose

JSP – Jacketed Soft Point

SWC – Semi-Wadcutter

Blast Resistant Windows, Blast Resistant Doors

Blast protection must be considered in design when a facility is a potential target or when a building is located in the vicinity of a potential target. The blast from an explosion does not discriminate and will expand radially from its point of origin until it encounters a solid structure, such as a wall with windows and doors.

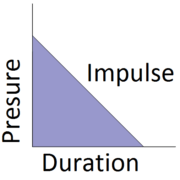

The blast then causes a pressure to be applied to the windows and doors for a period of time (duration). This creates an impulse or an amount of energy that is imparted to the window and/or door. A portion of this energy is absorbed by the window and/or door through the flexing of the glazing material. The remainder of the energy is transferred to the framing system and anchors.

Minimal rotation of the frame is allowed to ensure the glazing is retained. United States Bullet Proofing’s engineering professionals perform a complete computer analysis for each blast application. Anchor bolts are analyzed and furnished as part of a system package to ensure design criteria are satisfied during installation.

Blast Resistant Standards

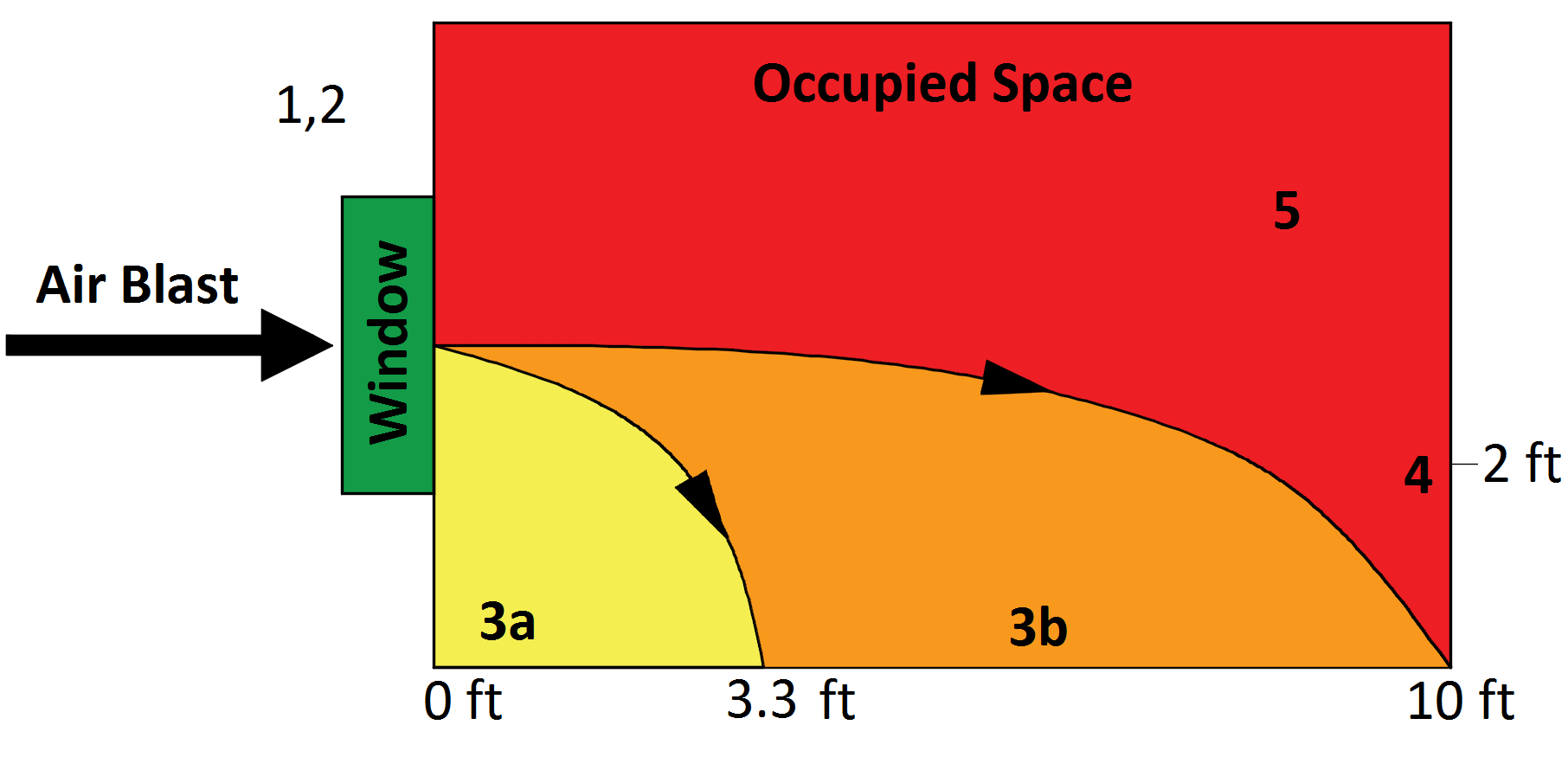

The graph and table show the performance criteria for blast resistant products. Pressure and impulse should always be specified when ordering a blast resistant product.

Note: Ballistic and forced entry protection can also be specified and achieved in a blast resistant product.

Impulse = 1/2 x Pressure(psi) x Duration(msec)

Note: U.S. Bulletproofing products meet and/or exceed UL 752 Ballistic Standards, GSA Blast, and DOD Forced Protection/Anti-Terrorism Criteria. Test reports are available upon request.

| Performance Condition | Protection Level | Hazard Level | Description of Window Glazing Response |

|---|---|---|---|

| 1 | Safe | None | Glazing does not break. No visible damage to glazing or frame. |

| 2 | Very High | None | Glazing cracks but is retained by the frame. Dusting or very small fragments near sill or on floor acceptable. |

| 3a | High | Very Low | Glazing cracks. Fragments enter space and land on floor no further than 3.3 ft. from the window. |

| 3b | High | Low | Glazing cracks. Fragments enter space and land on floor no further than 10 ft. from the window. |

| 4 | Medium | Medium | Glazing cracks. Fragments enter space and land on the floor and impact a vertical witness panel at a distance of no more than 10 ft. from the window at a height no greater than 2 ft. above the floor. |

| 5 | Low | High | Glazing cracks and window system fails catastrophically. Fragments enter space impacting a vertical witness panel at a distance of no more than 10 ft. from the window at a height greater than 2 ft. above the floor. |

Forced Entry

Forced entry is the attempted penetration of a door, window and/or wall using a wide variety of tools. These tools may include, but are not limited to sledge hammers, pry bars, wood splitting mauls, fire axes, battering rams, gasoline, acetone, propane torches and CO2 fire extinguishers. The number of people, the tools used, and the duration of the attack vary among the standards used to measure forced entry resistance. One of the most stringent standards is used by the Department of State for overseas embassies and diplomatic facilities. United States Bullet Proofing is proud to be one of only a few companies in the world certified by the Department of State to build forced entry products to this standard. Other standards include ASTM F1233 for glazing material, ASTM F588 for windows, and ASTM F476 for doors. These standards have multiple levels of ratings based on the severity of the threat.

Storm Impact

Storm Impact refers to the damage caused to buildings by violent storms with high wind speeds which can turn loose items into projectiles that can penetrate a building. US. Bullet Proofing offers a full line of products that are tested to protect buildings from violent storms including tornadoes or hurricanes.

The most common and robust product standard testing for storm impact is FEMA 361-21 and ICC500-21 which U.S. Bullet Proofing has certified to meet in order to adhere to the highest standard of storm impact protection.