BALLISTIC STANDARDS

The most common ballistic standards are UL 752 and the National Institute of Justice (NIJ)’s 0108.01. Typically, UL 752 is the most common standard used because it is more modern and independently verified. It also considers the penetration as well as injuries that could be caused by the spall from ballistic penetration, and it is more directly relevant to the construction industry.

When ordering products, it’s important to specify the required degree of ballistic protection you need.

The Need for Bullet-Resistant Products and Ballistic Standards

The ratings for bullet-resistant glass are calculated based on the protection the glass offers, the number of rounds fired before it breaks, as well as the size of the weapon used. The projectiles fired by high-caliber, high-velocity weapons deliver the greatest amount of force to the target. This requires stronger bullet-resistant glass, which offers a higher capacity for absorbing energy from the projectile.

To be at the highest bulletproof glass rating, the entirety of the system, including the glazing material, frame, and anchors, must be capable of absorbing force from the projectiles. Simply having bulletproof glass installed in the framing system is not enough. The entire system must be rated high enough to ensure the maximum level of protection. Our engineers design blast protection doors and windows that achieve the level of security your facility needs.

UL 752 Protection Standards for Bullet-Resistant Glass

U.S. Bullet Proofing recognizes that the UL 752 standard is the foundation for ballistic safety ratings regarding bullet-resistant glass. The recently introduced 12th edition marks a significant leap forward in ensuring the integrity and reliability of protective materials. The 12th edition standard was developed because it addresses critical inconsistencies found in previous versions, providing clearer, more in-depth guidelines for manufacturers and greater assurance for end-users.

A key difference from the 11th edition is the departure from a hierarchical rating system. The 12th edition now employs distinct, non-hierarchical classifications for handguns (HG), rifles (RF), and shotguns (SG), categorizing them based on ammunition type and ballistic characteristics. This change eliminates previous ambiguities where a higher rating didn’t always guarantee protection against all lower-rated threats.

The 12th edition also introduces vastly improved testing protocols. It mandates testing more samples of a material, with more shots per sample, and specifies more precise shot groupings. Using this methodology, along with its clear requirements for shot placement and sample conditioning, ensures our bullet-resistant glass products are tested under the most realistic and demanding conditions, offering unparalleled protection when it is needed most.

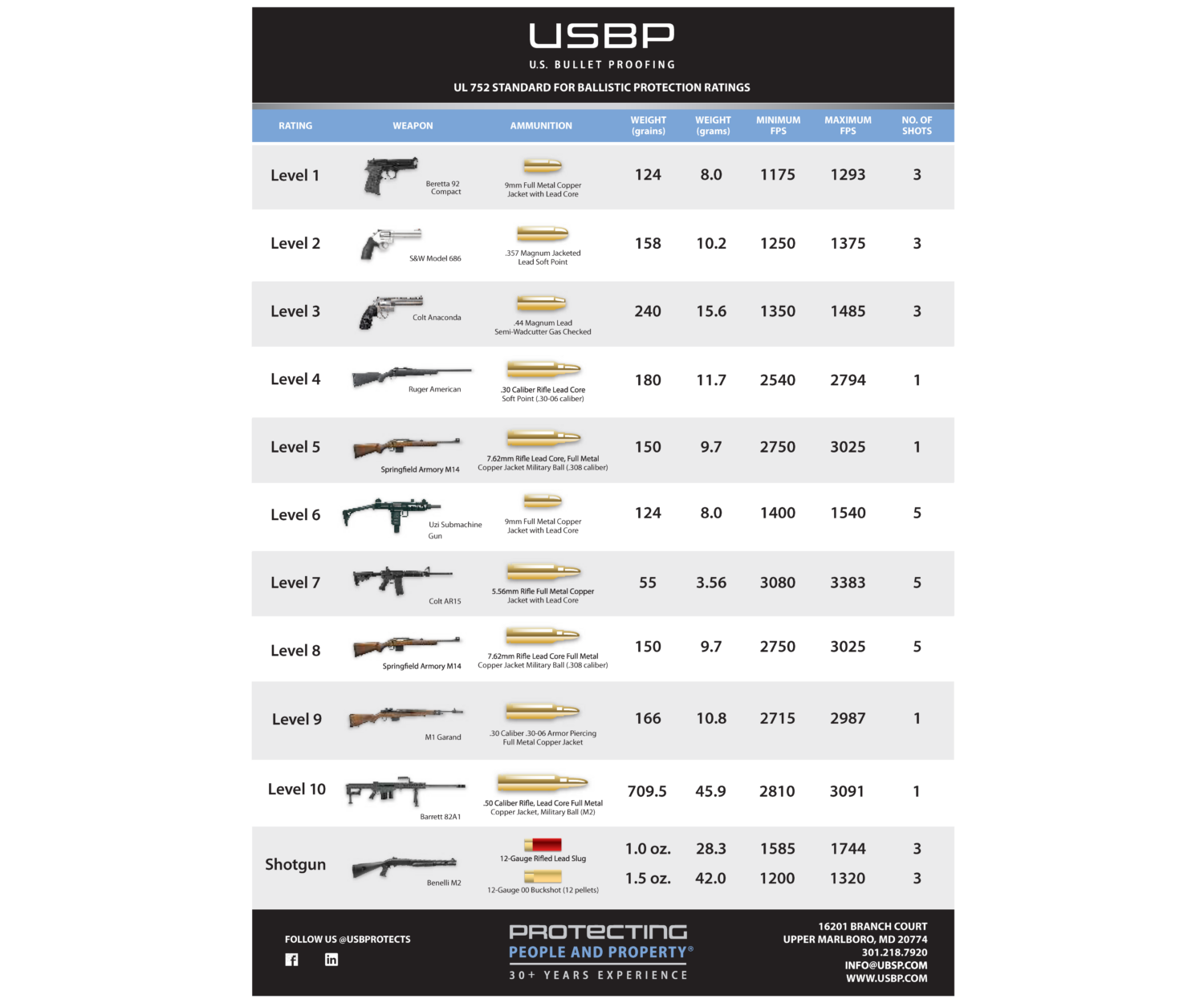

UL 752 11th edition involves separating bullet-resistant ratings into numeric levels. The details below give you a closer look at how UL 752 standards in the 11th edition work:

- Level 1 Rating: Provides protection from small caliber handguns up to 9mm and is often used for gas stations, transaction windows, retail and convenience stores, and pharmacies.

- Level 2 Rating: Provides protection from large caliber handguns up to .357 magnum and is commonly used in financial institutions such as banks, credit unions, and check cashing businesses.

- Level 3 Rating: Provides protection from large bore, large caliber handguns up to .44 magnum, and is frequently specified in high-risk and high-occupancy public buildings, including schools and government facilities, as well as law enforcement, courthouse, and prisons.

- Levels 4-8 Ratings: Provides protection against automatic weapons, assault rifles, and large caliber rifles. Levels 4-8 are mostly used in embassies, government facilities, and military applications.

A proper threat and risk assessment will help determine what level of protection your organization needs according to the UL 752 standard. Consulting with our team early in a project can save time, money, and ensure the glass, walls, and frames in your facility match the security requirements necessary to protect it.

NIJ Standard 0108.01

The NIJ 0108.01 is a common ballistic resistance performance standard established by the National Institute of Justice (NIJ). It is a less common standard, but it provides a valid means to classify the ballistic ranks required for construction products.

NIJ Standard 0108.01 Ballistic Resistant Protective Materials

- AP – Armor Piercing

- LRHV – Long Rifle High Velocity

- FMJ – Full Metal Jacket

- RN – Round Nose

- JSP – Jacketed Soft Point

- SWC – Semi-Wadcutter

| ARMOR TYPE | TEST AMMUNITION | RQD. HITS PER SPECIMEN |

|---|---|---|

| I | LRHW Lead 38 Special RN Lead | 5 5 |

| II-A | 357 Magnum JSP 9mm FMJ | 5 5 |

| II | 357 Magnum JSP (higher velocity round) 9mm FMJ (higher velocity round) | 5 5 |

| III-A | 44 Magnum, LeadSWC Gas Checked 9mm FMJ | 5 5 |

| III | 7.62mm, 308Winchester FMJ | 5 |

| IV | 30-06 AP | 1 |

ASTM F3561-22 Standard

The ASTM F3561-22 standard is a critical development in modern security. This standard evaluates a barrier’s ability to resist forced entry after it has been subjected to a simulated active shooter attack. It addresses a crucial real-world scenario where someone might shoot out a portion of a door or window to then gain access.

The goal of ASTM F3561-22 is not to stop the bullet itself, but to ensure the barrier remains intact to prevent a physical breach and delay entry. Products meeting this standard often buy valuable time for occupants to react and for first responders to arrive.

This standard is vital for enhancing security in education, government buildings, and financial offices.

Ballistic Glass Windows and Doors

U.S. Bullet Proofing understands the importance of protecting people and property, which is why we’re committed to engineering and manufacturing elite ballistic glass windows. Our windows feature multiple layers of glass in varying thicknesses. The higher the number of layers and the thicker the glass, the better they are at stopping bullets and other ballistic threats. Ballistic glass windows that incorporate laminated glass often utilize special polycarbonates, which provide the most protective glazing available.

Contrary to popular belief, bullets don’t bounce off ballistic glass windows. The multiple layers of reinforced glass gradually erode the velocity of the bullet, absorbing its kinetic energy and slowing it down enough that it doesn’t fully penetrate the window.

Our customized solutions serve a wide range of applications:

- Academic buildings: Create reinforced entry points to ensure the safety of students and educators including windows, doors and reception windows in the security vestibule or entrance to the building.

- Police stations: Incorporate high-level security solutions for front desks, interview rooms, and detention areas.

- Financial institutions: Depend on advanced ballistic solutions to protect tellers and assets from armed robbery.

- Pharmacies: Benefit from secure perimeters that safeguard medications and personnel from potential threats.

- Retail stores: Prevent smash-and-grab incidents and deter armed intruders from interfering with retail locations.

Reach out to U.S. Bullet Proofing for Product Details

U.S. Bullet Proofing is a pioneer in the design and supply of aluminum window and door systems that provide high-level protection from ballistics, blast, storm impact, and forced entry. Our job is Protecting People and Property®, and we take that responsibility seriously, as seen in the quality of products we provide, the scale at which we operate, and the breadth of projects that involve our solutions.

Contact one of our sales representatives to learn more about how we can help you with your next security project.