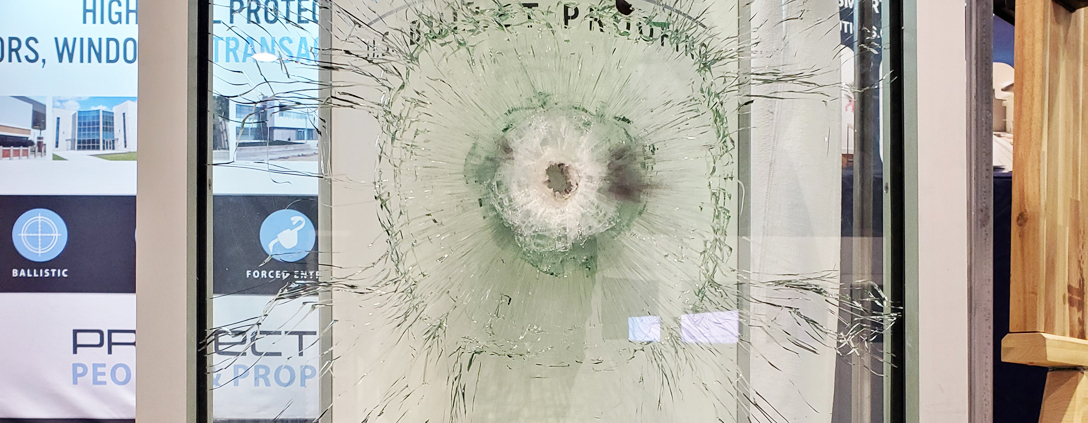

Types Of Bullet Resistant Glazing

By design, all bullet resistant glazing is not created equal. There are various types of bullet proof glass, each made to offer a different level of protection.

Essentially, there are four popular configurations of bullet resistant glazing available. The right choice for your safety, or that of your business, might not be right for the threats faced in other environments — schools, government buildings, guard houses, etc.

Know, too, that not all bullet resistant glazing is actually glass. Layers of various materials go into different types of bullet proof glass.

U.S. Bullet Proofing offers glazing that meets the highest levels of ballistic and blast protection available. UL Standard 752 rates ballistic protection at Levels 1-8, and we have products available to provide protection at all levels, including glass that can meet ballistic and blast protection requirements.

What type of glass is bullet proof? What is the right bullet proof glass for you? We’ll talk about the varieties available, but first:

Understand Your Needs

If you’re retrofitting an existing building with bullet proof glass, you may have to adapt the product to the architecture — or vice-versa, if the threat level necessitates it. Ballistic protection ratings are based on the number of rounds and size of weapons capable of being withstood. Expectations of the firepower that might threaten a bank or school drive-thru bank differ from that for a military complex or government building.

Types of Protection

Let’s examine the basic varieties of bullet resistant glazing: acrylic, polycarbonate and glass-clad polycarbonate.

Acrylic

Essentially, acrylic is a monolithic sheet of hard plastic. If at least an inch thick, acrylic plastic is bullet resistant on its own. This type of glazing is the most common in business applications requiring low-level protection.

In addition to having greater impact resistance, since it doesn’t contain any actual glass, acrylic is stronger and lighter than traditional glass. It is also easily customizable in that it can be cut, routed, drilled, polished and otherwise altered depending on your needs. Because it allows nearly perfect passage of light, acrylic is largely used in indoor applications, for applications such as baffle windows, while tinted products are used to face exteriors.

In terms of ballistic resistance, acrylic offers Level 1 or 2 protection, depending on the product. A Level 1 protects against three jacketed 9mm rounds, while a Level 2 is rated to stop three shots from a .357 Magnum. Acrylic repels the bullets, whereas layered bullet proof glass “catches” them.

Polycarbonate

Here’s your bullet-catching glass. Polycarbonate is softer than acrylic. It is layered, which gives the product strength and accounts for its noticeable tint. More than 80% of light passes through polycarbonate. It’s light, and therefore relatively easy to work with even when dealing with greater thicknesses, but it can be more prone to scratches in some applications.

One important note to keep in mind about polycarbonate is that it must be cleaned with gentle, non-abrasive cleaner. A typical household cleaner, such as your standard glass cleaner, can cause a chemical attack and deteriorate the makeup of the polycarbonate.

Because it is soft, polycarbonate absorbs the energy from the bullet. Instead of deflecting off the surface of the glass as it can do with acrylic, a bullet simply becomes embedded in polycarbonate.

Levels of protection vary with the thickness of the polycarbonate. For example, a ¾-inch thickness provides Level 1 protection, an inch takes you to Level 2 protection, and 1¼ inches takes you to Level 3. In addition to its bullet resistance, polycarbonate affords greater protection against forced entry. Polycarbonate can take an hour of pounding from a sledgehammer that might breach acrylic in a few minutes.

Polycarbonate is also more expensive than acrylic or glass, and thus is frequently layered with other materials to reach necessary levels of ballistic resistance.

Glass-Clad Polycarbonate

This layered material will be the strongest “glass” you can install. Essentially, a sheet of polyurethane is the middle layer. Glass sandwiches that center. More polyurethane is added atop the glass layers, and a coat of polycarbonate on each side. Typically, glass-clad polycarbonate is at least an inch thick and usually more.

While fabricating glass-clad polycarbonate into a seamless system can be challenging, it can be built up to greater and greater thicknesses, meaning its strength is limited only by how much thickness your project can accommodate.

If you need to stop shots from an M16 or an AK-47, glass-clad polycarbonate is the way to go. It can be manufactured to Level 1 or Level 8 protection, and everything in between.

Glass-clad polycarbonate holds up great against high traffic, weather, forced entry, explosions and high-velocity winds (hurricanes, tornados, etc.).

All-Glass

Glazing comprised completely of glass and providing ballistic protection is available for most levels of UL 752 protection.

Glass is typically thicker and heavier than some of the materials listed above but, it does not suffer the same vulnerability to chemical attacks from household cleaners. When using glass for bullet proof glass, it’s also important that it offers little to no spalling, which are small fragments of glass that can project from the glazing in the event that it is compromised by a projectile. These fragments can cause harm to those located in the vicinity when it is faced with a threat.

Solutions as Unique as You

We hope you now have a better understanding of the levels of bullet resistant glass. No matter your desired level of protection and design constraints of your project — be it modifying existing buildings or new construction — U.S. Bullet Proofing can help you make an informed decision when choosing from our array of bullet resistant products.